Aug. 21, 2020

C-shaped steel machine process: the strip steel is fed from the tail of the equipment, and is pressed into a C-shaped steel machine through various press rolls. The C-shaped steel machine is sent out from the head. In the traditional process, the C-shaped steel needs to be manually cut at a fixed length after it is pressed and then transported to the punch The hole equipment is punched according to the size required by the customer, and the production cannot be continuous, and the efficiency is not high. Through the gradual improvement of the production process, the automatic control of the entire process is finally realized, which has improved the production efficiency and increased the technical content and additional equipment of the customer.

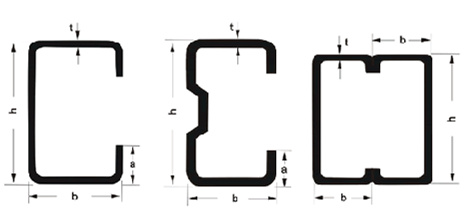

C channel drawing

C channel steel is an efficient and economical cutting profile, so that the wall thickness of the C-shaped steel machine can be made very thin, and the production process is greatly simplified, and the production efficiency is improved. It can produce average wall thickness that is difficult to produce by general hot rolling methods. Various profiles with complex cross-sections and cold-formed steels of different materials.

C channel roll foming machine production line mold used in this machine requires an upper mold and six lower molds of the same specifications and dimensions. First install the upper mold and a lower mold, and the lower mold is directly installed on the hexagon On the wheel table, the upper mold is installed on the bottom surface of the sliding seat, and a backing plate of appropriate thickness is placed to ensure that after the upper and lower molds are closed, the clearance around the edges is even, and the interval between the upper and lower molds is the thickness of the required tile. The above mold shall prevail, the worktable shall be rotated, and the other five lower molds shall be installed. After all the upper and lower molds are installed, the pressing can be carried out.

C channel process method

Uncoiler——Leveling——Forming——Cutting

Superda complete quality assurance system, strict management system, strong production capacity and advanced technical equipment to ensure While the products are of high quality and high output, they also endow products with strong market competitiveness.

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377