Cheap price tube roll forming machine for making stainless steel door frame special tube.

Product Description

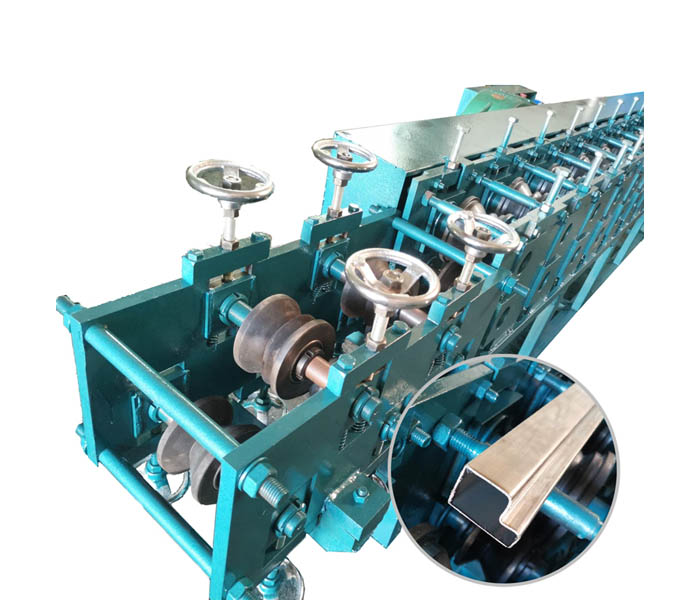

Stainless steel round tube change into special shape tube forming machine which for producing door frame tube.

Round tube change into door frame using tube equipment photo

Stainless steel door frame tube forming machine technology

(Raw material stainless steel tube thickness 0.7-0.8mm)

| Model | SP-48 |

| Motor power | 5.5KW |

| Reducer | 350 type |

| Feed material | iron pipe |

| Feeding round tube diameter | 1.5 inch (cun) |

| Forming Roller | 8 forming + 2 straightening |

| Working speed | 10 meters / minute |

| Roller material | GCr15 heat treatment after finishing |

| Spindle material | 40Cr after quenching and tempering |

| Transmission mode | 1 inch chain sprocket drive |

Main maintenance of door frame tube forming machine

Circuit, Pay attention to the cleaning of the circuit board, regularly clean the dust of the strong and weak electric boxes, keep the electric boxes dry and prevent moisture.

Oil circuit, Check for oil leakage in various parts of the oil circuit, and deal with it in time. Prevent the piston rod from scratching and oil deterioration.

Machinery, Check the transmission parts of the machine.

Special tube photos made by tube roller mill.

Round tube pressure square tube shaped tube forming equipment advantage.

The round tube pressing shape tube forming equipment, It is a machine to process the round pipe steel used in waste construction into special-shaped pipe. Complete, waste utilization, turning waste into treasure, round tube pressing square tube & shaped tube forming machine.

The specific parameters and advantages of the equipment produced by Superda.

1. The equipment is controlled by PLC, and safety protection is set during normal production.

2. The bed is welded steel plate. And for tempering to remove internal stress and avoid deformation of the fuselage.

3. The forming frame is a cast iron structure and has been tempered. High strength and long life.

4. The material of the roll shaft is 40Cr, and the hardness is HB280 after quenching and tempering.

5. The material of the forming mold is GCr15, quenched, and hardness: HRC56-62℃.

6. The transmission structure is gear box transmission. Each forming frame has a gear box, which can ensure the equipment time, intensity operation, and long service life. It is mainly used for the construction & furniture & hardware. The distribution box of this machine adopts touch screen display, computer numerical control, and software supports remote computer programming and other functions. The machine has the advantages of multiple functions, reasonable structure and simple operation.

For the site or warehouse where special-shaped steel pipe products are stored, it should be selected in a clean, tidy, well-drained place, and away from harmful gases or dust in factories and mines. Weeds and debris should be swept away on the ground to keep the steel tidy. In the warehouse, it should not be stacked with materials that are corrosive to steel such as acid, alkali, salt, and sensitive soil. Different types of steel should be stacked separately to avoid confusion and contact with corroded objects.

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377