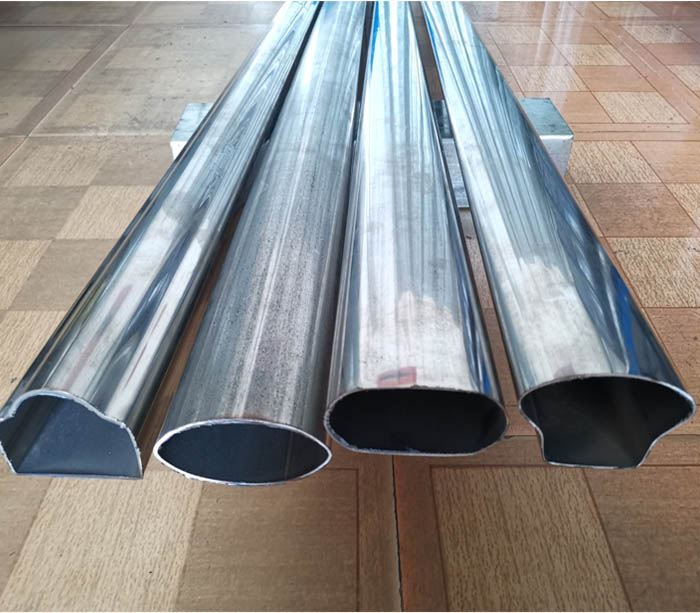

Stainless steel elliptic pipe roll forming machine manufacturers China for making ellpise tube, oval pipe, flat-oval pipe, stainless steel mushroom tube.

Product Description

Superda pipe roll forming machine for making Fan-shaped tube, P-shaped tube, grooved tube, oval tube, square pipe, rectangle pipe, elliptical pipe, special-shaped tube and other custom pipe roll forming machine manufacturers.

Stainless steel elliptic pipe, mushroom shape, flat oval tube mady by Supeda roll forming machine.

Stainless steel handrail & ellipse tube & oval tube & mushroom pipe roll forming machine parameter.

| Model | SP-IN4 |

| Motor power | 11KW |

| Reducer | 4000 type |

| Feed material | iron pipe |

| Feeding round tube diameter | 1.5 inch (cun) |

| Forming Roller | 8 forming + 2 straightening |

| Working speed | 10 meters / minute |

| Roller material | Cr12 heat treatment after finishing |

| Spindle material | 40Cr after quenching and tempering |

| Transmission mode | Gear |

Stainless Steel Elliptic Pipe Production Video

Product Features

Steel Round Pipe change into ellipse pipe &flat tube & square pipe ect customized pipe forming machine operation guide

1. Develop safe operating procedures. Do not touch the mold during the operation of the unit. If you need to touch it during work, your hands should be placed in the direction of the pipe. Operators should have fixed positions, not change at will, and keep a record of shifts.

2. Before driving, check whether the lubrication points of the steel square tube forming machine are filled with corresponding lubricants. Pay special attention to the high-speed lubricating grease that is relatively high-temperature resistant to the main shaft of the flying saw. Fill it once every two days, two or three times each time. It should not be added too much. If the heat dissipation is not good, it will cause excessive heating and even bearing dead.

3. The temperature of the welding extrusion is too high. It is recommended to use a synthetic composite aluminum-based grease (SY1414-80) that can withstand high temperatures and use under humidity conditions.

The large hexagonal nut and the upper pull plate should be adjusted at the same time to avoid that the squeeze roller is not perpendicular to the plane of the worktable, which may damage the thread of the squeeze roller. At the same time, pay attention to check the squeeze roller bearings. The working environment here is harsh and the bearings are easily damaged. If abnormalities are found, the bearings should be replaced in time to avoid greater damage.

4. The gear box is lubricated with gear oil with good fluidity, generally 230# gear oil (for reference only due to the difference between north and south). Pay attention to frequently check the bearings of the gearbox of the steel square tube forming machine. Pay attention to the working condition of the gearbox during work. If you hear abnormal sounds, you should check the gearbox bearings in time. Bearing-type wearing parts should be checked. Once damaged, it cannot be repaired in time. It is easy to cause damage to gears, etc., and the loss will be greater.

5. Precautions for flying saw: pay attention to adjusting the flying saw one-way valve (the one-way valve of this machine is the air outlet throttle) so that the production speed of the flying saw trolley and the steel pipe is basically the same or slightly slower than the steel pipe speed, so that when sawing It can ensure the speed synchronization of the flying saw trolley and the steel pipe to avoid damage to the saw blade. Before starting each time, check whether the bolts of the driving parts of the flying saw are loose and whether the mechanical parts are damaged, and deal with it in time to avoid incidents. It is forbidden to stand before and after the flying saw is in operation to avoid injury.

6. The pipe forming machine should be dismantled and cleaned regularly according to the working conditions, the vertical roller device and the stolen goods in the welding seam extrusion device should be cleaned, and an appropriate amount of grease should be applied for rust prevention and lubrication. The horizontal roller frame should also be scrubbed regularly according to the situation to remove the dirt, and greased on the guide rail and screw rod on the inner side of the frame.

7. During the operation of the roll, the tightening of the nuts before and after the horizontal roll should be monitored. If the nuts are loosened, the machine should be stopped immediately to eliminate the fault.

8. When the electrode is reversed, the strip retreat distance generally does not exceed 300mm.

9. The upper and lower adjustment nuts in the same group of horizontal roller racks should be adjusted at the same time, so that the horizontal roller shaft is always in a horizontal state to avoid jamming and forced adjustment. When the square tube is produced by the round-to-square process, the lower shaft slider of the sizing horizontal roller and the lower sizing vertical roller should be raised according to the roll shape variable. The method of keeping the center unchanged makes the round square more smooth and reduces the resistance. small. If it is not raised, all deformations will appear on the top and the pipe will be pierced down, which will increase the resistance, waste electricity and increase equipment loss.

10. The upper and lower rolls of the open-hole horizontal roll stand should be able to accommodate the thickness of the strip and leave a gap, otherwise it is easy to cause steel rolling and damage the parts.

11. When adjusting the size and shape of the finished pipe, it is strictly forbidden to adjust the amount too large. After one roller rack is adjusted, the adjacent roller racks should also be adjusted accordingly to achieve the basically uniform load of each roller.

12. When the roll is installed, the inner hole and shaft should be coated with appropriate amount of oil, and the bearing should be coated with enough grease to facilitate loading and unloading. The coolant should be directed at the working surface of the roll and should not be directed at the bearings or other parts.

13. The equipment should be overhauled regularly, cleaned and maintained regularly.

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377