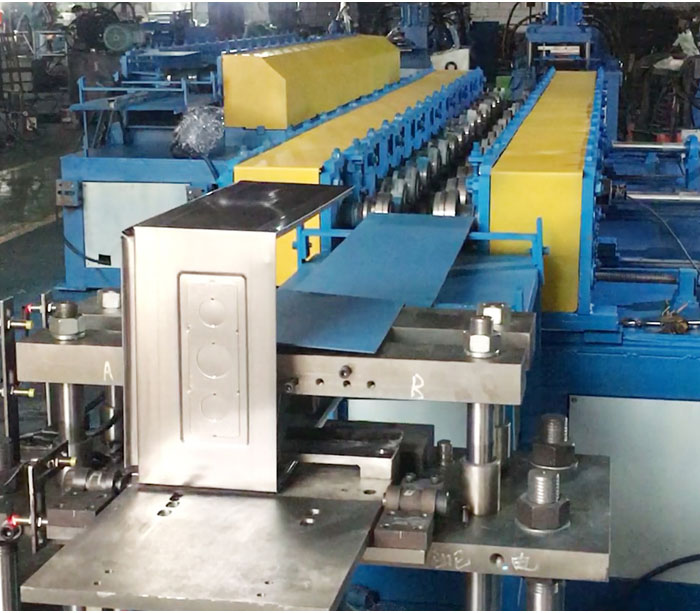

Automatic power distribution box production line manufacturer for 150-400mm depth electric enclosure forming and bending process.

Product Description

Automatic Galvanized Steel & Stainless Steel Enclosure Box Production Line Projector Solution

Product specifications: height adjustable 300-1200mm, depth adjustable 160-400mm.

Electrical enclosure Production machine technical parameters

Item | Technology parameter | |

Material | Material | cold-roll strip,galvanized steel strip |

Thickness | 1.0-1.5mm(base on 1.5mm design, when T.1mm effect alittle not good as 1.5mm) | |

Coil Inner | Ф360—Ф510 | |

Process | Form Speed | 0-13m/min |

Length | Not limit | |

Quality | Length Precision | L≤1000mm:±0.5㎜ |

Straight, Deflection | L≤1000mm,Bend no more than 1mm;Deflection no more than 2mm | |

Forming size | As per design | |

Steel Enclosure Box Making Process

Uncoiler→ Straightening→Servo feeder→Hydraulic device→ Guide device → Roll forming machine →Bending device

Distribution box production line technology explaination

This production line is equipment for production of distribution boxes. The strip coil to be processed is manually placed on the uncoiler, and then corrected and tensioned. After leveling, it enters the hydraulic pre-punching and punching notch, and is sent to the forming machine by the guide device to form. Under the frictional damping action of the forming roller and pressure roller, after entering the bending part at a linear speed of 0-13m, the box is cut and bent as required, and then manually packed away. This production line produces 2-3 enclosures per minute. the production box quantity speed according to different product specifications.

Electric box production line main technical parameters

1.Details of accessory brand

No. | Name | manufacturer |

1 | Encoder | Omron |

2 | Touch Screen | Mitsubishi |

3 | Programmable controller (PLC) | Mitsubishi |

4 | Low-voltage circuit breaker | Chint |

5 | AC contactor | Chint |

6 | Inverter | Mitsubishi |

7 | Hydraulic Solenoid Valve | Shun Xin, Taiwan |

8 | Guide rail | Hiwin Taiwan |

9 | Server System | Mitsubishi |

2.Feeding specifications

a. Applicable materials: cold rolled coil, galvanized coil

b. Material quality: Domestic GB standard

c. Tensile strength: δb≤780Mpa (Max.)

d. Yield strength: δs≤510Mpa (Max.)

e. Material thickness: 1.0-1.5mm

f. Material width: 200-450mm (Max.)

g. Inner diameter of steel coil: Φ360mm-Φ510mm

h. Outside diameter of steel coil: Φ1250 (Max.)

i. Steel coil weight: 3 t (Max.)

3.Forming parameters

a. Number of forming staion: 16 sets of roller

b. Spindle specification: Ø48mm 40Gr quenching and tempering

c. Roller material: Gr12 mold steel heat treatment

d. Integral archway: precision machined from 25mm steel plate, the hole distance error is less than 0.1mm

e. Base plate thickness: 20mm

4, forming ability

a. Outside diameter of coil: Φ1250mm (Max.)

b. Material forming thickness: 1.0-1.5mm

c. Product width 160mm-400mm adjustable

5.Speed parameters of forming unit

a. Linear speed 0-13m / min

b. Acceleration time < 30 seconds

6, Forming accuracy

a. Shear length tolerance: ≤ ± 0.5mm / m

b. Width tolerance: ≤ ± 0.5mm

c. Sickle curve: ≤2mm / m

d. Burr: ≤0.1mm (new blade cutting ordinary carbon steel plate with reasonable clearance)

e. Height tolerance: ≤ ± 0.5mm

The above tolerances are based on the first-grade steel coils with flat and edgeless waves.

7.Other equipment parameters

a. Power supply: 380V / 50HZ / 3PH (Or Custmized)

b. Installed capacity: about 32Kw

c. Forming speed: 0-13m / min

d. Cutting method: forming then cutting

e. Driving motor:

Straightener machine motor 2.2KW

Hydraulic punching 15kw,bending and cutting 5.5KW

Forming host motor 7.5KW

Servo motor 2KW

f. Floor area (approximately): length 30m × width 3m

(Roll Forming 7mX1.5m)

g. Production line direction: from left to right

(facing the unit from the operation table).

h. Equipment color: (Customer choice)

i. Unit equipment design can meet 12 hours of continuous production

j. Operating environment:

1: power supply voltage: 380V ± 10% / three-phase four-wire, frequency: 50HZ total power: about 32KW

2: Ambient temperature: 0-40 ° C, relative humidity: 60-95% RH.

Power distribution box production line devices:

No. | Machine name | QTY | REMARK |

1 | Uncoiler | 1 | |

2 | Straightener | 1 | |

3 | Servo Feeder | 1 | 2kw Mitsubishi motor |

4 | Servo Hydraulic machine | With mould | |

5 | Guide device | 1 | |

6 | Forming machine | 1 | |

7 | Hydraulic bending cutting | 1 | With mould |

8 | Control system | 2 |

Product Features

Guarantee of Quality

Superda guarantee bank steel enclosure & wall mounted electric distribution box roll forming line design accordance with clients required drawing, machine is brand new. Specification and performance as stipulated in drawing and operation with good smooth.

Automatic metal enclosure roll forming machine advantage

1, High efficiency production line, one minute can producing 2-3pcs

2, PLC control system, automatically and easy handle.

3, Gcr15 roller with quench process, hardness reach HRC60-65 ℃.

4,Tracking cutting system with Cr12 Cutting blade.

Formed distribution box very smooth easy for your next process welding.

Model and Meaning

Steel enclosure machine producing combination metal cabinet enclosure for outdoor indoor distribution box panel forming and bending.

Box roll forming machine accuracy

a. Shear length tolerance: ≤±0.3mm/m

b. Width tolerance: ≤± 0.3mm

c. Bending: ≤2mm/m

d. Burr: ≤0.1mm (new cutting edge cuts carbon steel plate in reasonable clearance)

e. Height tolerance: ≤±0.3mm

bove tolerance with flat edgeless one-stage steel coil As a prerequisite.

Surface quality: The surface of the finished product after processing does not add any processing defects.

High efficiency enclosure production line, one minute can produce 3 pcs cabinet enclosure forming and bending.

Technical Parameters

Wall mounted electric distribution box roll forming machine for production different size cabinet

Electrical steel box parameters of the equipment

a. Power supply: 380V/50HZ/3PH, can customized as per user country.

b. Installed capacity: about 31kw.

c.Forming speed: 0-13m/mind.

d.Shearing method: Servo front shear

e. Drive motor: Unwinder motor 4KW.

leveling motor 2.2KW.

hydraulic punching cutting and hydraulic tensioning motor (two sets) 11KW+7.5KW. forming main engine 5.5KW.

servo motor 2KW

f. Floor area (approx.): length 24m × width 3m (host specification 7mX1.7m)

g Production line direction: from left to right (on the console facing the unit).

h. Equipment color: (customer selection)

i. Superda steel box equipment design can meet 12 hours of continuous production

j. Operating environment

1: Power supply voltage: 380V ± 10% / three-phase four-wire,frequency: 50HZ Total power: about 31KW2: Environment Temperature: 0-40 ° C, relative humidity: 60-95% RH.

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377