Electrical cabinet 9 fold profiles roll forming machine for production nine bend frame server rack mounting panel

Product Description

Electrical Cabinet 9 Fold Profiles Roll Forming Machine

Automaitc electric factory using cabinet frame roll forming machine for electric cabinet 9 fold rack, electronic box pole, metal case frame which using in switchgear system, server case, low voltage panel building, control cabinet electrical instruments etc.

1,Technical parameters

| No. | ITEM | PARAMETER | REMARK | |

| 1 | MATERIAL | Type | Cold-rolled strip steel, galvanized sheet | |

| T.(mm) | 1.5mm | |||

| Yield Strength (Mpa) | Q235 | |||

| 2 | Forming product Width | 43.5mm | ||

| 3 | Forming speed (m/min) | 2-6m | Including welding | |

| 4 | Forming main power (KW) | 11 KW*2 pcs | FYR | |

| 5 | Hydraulic power (KW) | 18.5 KW | FYR | |

| 6 | Voltage | AC380V,50Hz,3P | ||

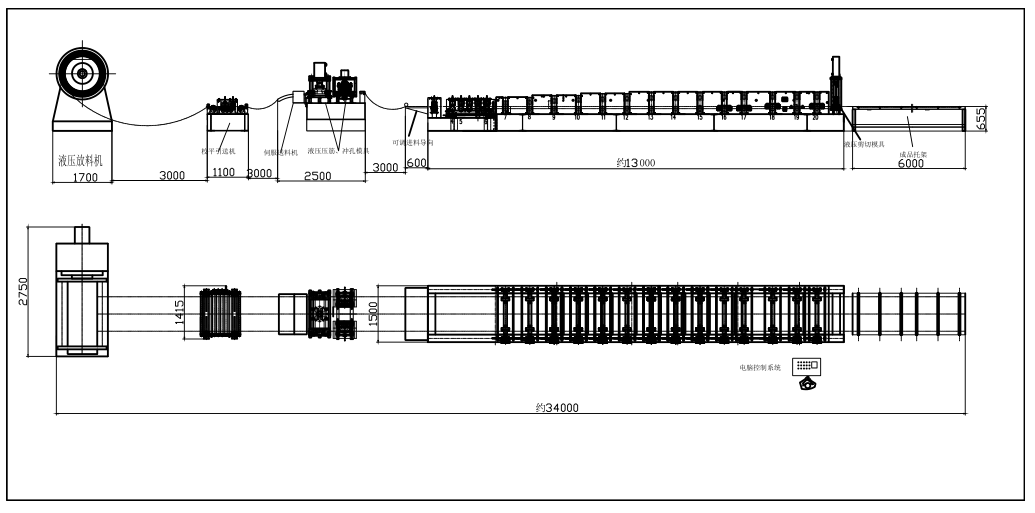

Electronic control panel 9 bend frame production line process

2 in 1 Uncoiler Straightening→servo feeder→punch → Guide device → roll forming machine → Roller welding →shear device (including knife)→ finished product rack

Layout as below

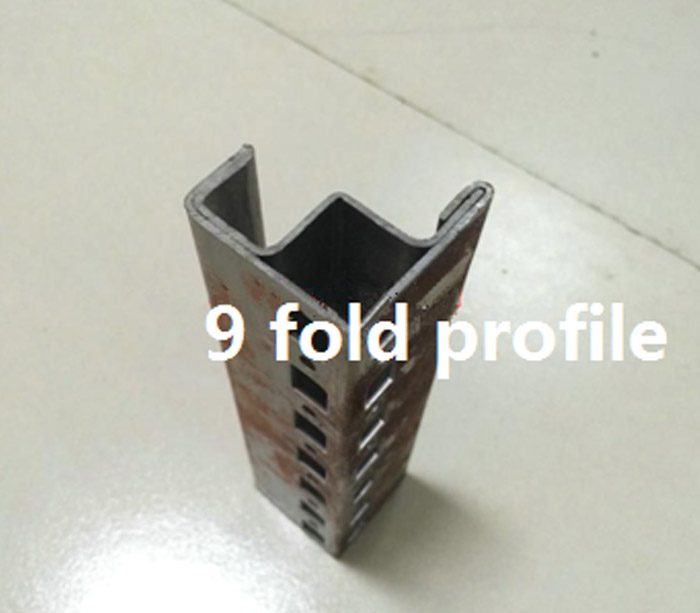

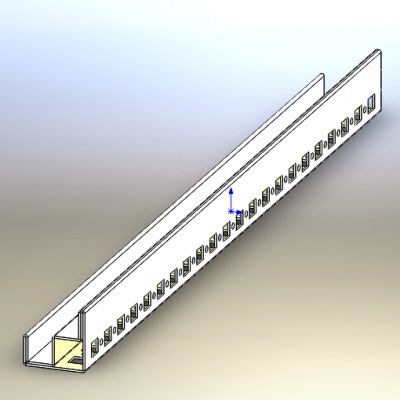

Formed 9 fold profile photo by roll forming production line

Nine bend rack drawing below roughly refer only, exactly can make based on client design

Roll Forming machine list

2, Cabinet frame 9 fold production line parameters

1), Uncoiler

3 tons of passive uncoiler

Steel coil for inner diameter: 350 - 450mm

Maximum load of steel coil: 3 tons,

tensioning method: manual tensioning

2), leveling machine

Leveling equipment: 7-roll leveling motor power: 3KW

Thickness adjustment method: screw adjustment and flattening shaft diameter: 40mm

3), automatic feeding system

Automatic feeding system motor power: about 2KW

4. Hydraulic press

Hydraulic Punch: Hydraulic Punch

Hydraulic station power: 7.5KW

Number of cylinders: 1 set

Number of die: 1 set

Punching pin material: GCr12mov

Limit: Light sense

5, roll forming system parameter

The base is welded by a square tube

Number of roller station: 28 station

Roller shaft diameter: 65mm

Roller shaft material 45#

Roller material: GCr15 fine turning process with quenching

Two sets of 11 KW motors

Forming machine structure: wall panel structure

Transmission mode: industrial drive chain

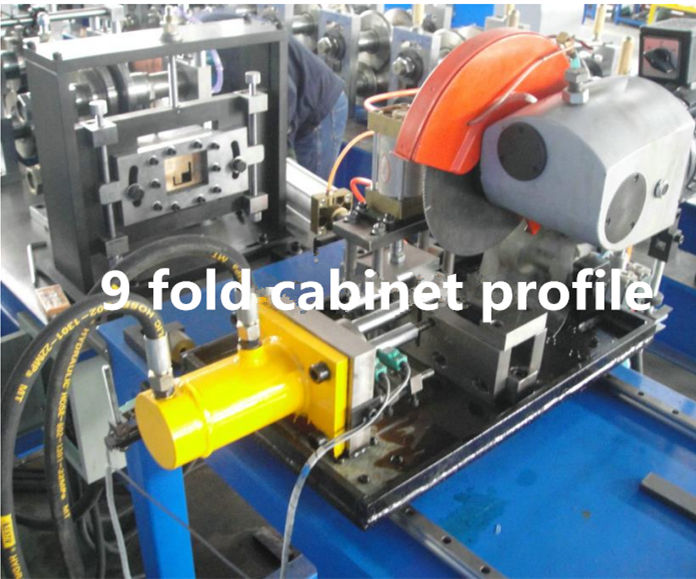

6, cut off

Cutting method: cut off the flying saw with water cooling

7, Electronic control system,

Speed control: inverter

PLC uses Panasonic brand

Encoder uses Omron brand

Touch screen adopts China Brand Touch Screen

The control system has its own power protection, overload protection, short circuit protection, and its own emergency stop button. (This button can be pressed if an accident occurs, and the device stops.)

Flat collect rack

Electrical control system

The entire line imported PLC control, LCD touch screen, man-machine interface. People interact with the PLC. Operator setting the program to run automatically (programmable control) and control process monitoring, production line operator control and modify the control parameters, and real-time monitoring the equipment status & parameters and fault indication. Workpiece length digital setting, adjustable length can be adjustable as well. Real-time monitoring of equipment operating status and fault indication.

Operation manual / automatic two styles. With manual and automatic switching function: In the manual mode, can be stand-alone operation, easy maintenance; In automatic mode, carry out full production run, in order to start; across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operating personnel Safety.

Machinery main components of the brand:

PLC control system: Siemens

Inverter: Taiwan Shilin

Encoder: Omron

Touch screen: Siemens

Some components are Schneider brand devices.

Devices completed 16 fold cabinet frame prodution line

| No. | Machine name | QTY | REMARK |

| 1 | Uncoiler straightener | 1 | |

| 2 | Servo Feeder | 1 | |

| 3 | Hydraulic machine/Punch machine | 1 | With mould |

| 4 | Guide device | 1 | |

| 5 | Forming machine | 1 | |

| 6 | Roller welding | 1 | |

| 7 | Follow Shear | 1 | Including knife |

| 8 | Collect rack | 1 | |

| 9 | Control system | 1 |

Cabinet frame machine accessories brand

| No. | Name | manufacturer |

| 1 | Motor & Reducer | Domestic brands |

| 2 | The main key bearing | Domestic brands |

| 3 | Inverter | Shilin |

| 4 | PLC Systems | Siemens |

| 5 | Low-voltage electrical | Schneider |

| 6 | Encoder | Omron |

| 7 | touch screen | Siemens |

| 8 | Hydraulic system | Domestic brands |

Product Features

Guarantee of Quality

Superda guarantee cabinet frame 9 bend rack roll forming line design accordance with clients required drawing, machine is brand new. Specification and performance as stipulated in drawing and operation with good smooth.

Electrica cabinet frame roll forming machine advantage

1, Electrical frame production line for producing 9 fold cabinet frame rack.

2, PLC control system, automatically and easy handle.

3, Gcr15 roller with quench process, hardness reach HRC60-65 ℃.

4,Tracking cutting system with Cr12 Cutting blade.

Model and Meaning

Customized design electrical cabinet frame roll forming machine with welding for producing control panel cabinet, electric cabinet rack, electronic box pole, metal case frame which using in switchgear system, low voltage panel building,electrical instrument.

Technical Parameters

9 Fold structure cabinet section and accessories list

PS-005 | 130 degree hinge |

PS-005-2 | Perforated hinged sleeve |

PS-006-1 | Corner plug |

PS-007 | Left and right hanging pieces (upper fixing pieces) |

PS-007(GJLS) | Pendant screws |

PS-008 | Bent plate (fixing part under the mounting plate) |

PS-008(FJLS) | Accessory screw |

and | Left slider (right) |

PS-008-1(Y) | Right slider (No. 1) |

PS-009-1 | Base plate accessories |

PS-009-2 | Floor screws |

PS-010-1 | Side plate accessories |

PS-010-2 | Side plate screws 5 * 7 |

PS-011-1 | Lock assembly (821) assembly |

PS-011-2 | Single door stop (upper and lower stop) |

PS-011-2-1 | Middle stop |

PS-013 | Hollow nut M6 * 17 |

PS-014-1 | Back plate screws |

PS-014-2 | Back plate screws |

PS-015 | Door panel bracket |

PS-016 | Iron tee |

PS-017 | Square nut M6 / 8 |

PS-018 | Locking lever (PS) |

PS-018-1 | Guide |

Mounting plate reinforcement | |

PS-023 | File bag (orange) |

PS-025-1 | Door stopper (door limit) |

PS-021 | M12 rings |

Bottom beam | |

Side beam | |

Side beam | |

9 fold profile (cold plate) | |

Reinforced square tube (1.0) |

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377