Uncoiler →Guide device→Straightening→Hydraulic press breach device → roll forming machine → hydraulic punch →shear device (including knife)→ finished product rack

Product Description

Two/Three wave guard rail roll forming machie

Guard rail produciton line process go through

Uncoiler →Guide device→Straightening→Hydraulic press breach device → roll forming machine → hydraulic punch →shear device (including knife)→ finished product rack

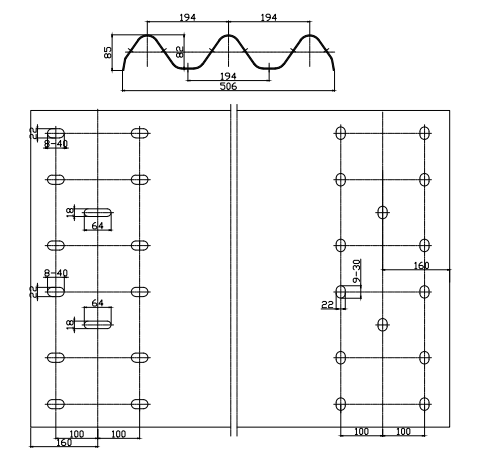

Three Wave Guardrail Drawing

Guard rail production line Hydraulic hole punching system

Function:Hydraulic punch breach (Mould 1 set)

Structure: set the length, automatic length measurement, automatic positioning reaches the set distance stop action , hydraulic cylinder driven punching die, stamping automatic shutdown.

Hydraulic system working pressure:16MPa

Hydraulic station:30KW( Hydraulic punch hole/shear use same station)

Main Forming machines (for panel width 310/506mm )

Forming Roller:19 stations,and add Rub-roll, To make sure the surface profile no scratches.

Gateway Panel:T.50mm steel, Heavy duty 。

Rolling speeding: 8-12 m/min。

Roller material:GCr15,overall quenching, hardness HRC56-62 ℃.

Motor power:18.5KW*2PCS。

Main Roller :¢95mm,45 #。

Equipment base: 45 # H type using welded steel plate.

Transmission: Gearbox drive.

Security: across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operator safety. And other gear in the chain and the staff could easily lead to injury transmission section covered with protective cover, to ensure the safety of workers.

Hydraulic Punch Machine /Follow shear

Hydraulic Punch machine

Follow shear (Cut style):Hydraulic cut(No blanking),Machine non-stop can cut product.

Knife material:Cr12,quenching hardness of up to HRC56-58 degrees.

Electrical control system

The entire line imported PLC control, LCD touch screen, man-machine interface. People interact with the PLC. Operator setting the program to run automatically (programmable control) and control process monitoring, production line operator control and modify the control parameters, and real-time monitoring the equipment status & parameters and fault indication. Workpiece length digital setting, adjustable length can be adjustable as well. Real-time monitoring of equipment operating status and fault indication.

Operation manual / automatic two styles. With manual and automatic switching function: In the manual mode, can be stand-alone operation, easy maintenance; In automatic mode, carry out full production run, in order to start; across the board with emergency stop buttons, easy to handle emergencies, to ensure that equipment and operating personnel Safety.

Guard rail production line brand for accessorries

| No. | Name | manufacturer |

| 1 | Motor & Reducer | Domestic brands |

| 2 | The main key bearing | Domestic brands |

| 3 | Inverter | Shilin |

| 4 | PLC Systems | Siemens |

| 5 | Low-voltage electrical | Schneider |

| 6 | Encoder | Omron |

| 7 | touch screen | Siemens |

| 8 | Hydraulic system | Domestic brands |

Completed Guardrail Production line including Devices

| No. | Machine name | QTY | REMARK |

| 1 | Uncoiler | 1 | |

| 2 | Hydraulic machine | 1 | With mould |

| 3 | Guide device | 1 | |

| 4 | Forming machine | 1 | |

| 5 | Hydraulic machine | 1 | With mould |

| 6 | Follow Shear | 1 | Including knife |

| 7 | Collect rack | 1 | |

| 8 | Control system | 1 |

Product Features

Two wave, three wave roll forming machine advantage

1, Highway guard rail production line for producing w beam barrier, 3 wave barrier, guardrail board.

2, PLC control system, automatically and easy handle.

3, Gcr15 roller with quench process, hardness reach HRC60-65 ℃.

4,Tracking cutting system with Cr12 Cutting blade.

Guarantee of Quality

Superda guarantee highway guard rail roll forming line design accordance with clients required drawing, machine is brand new. Specification and performance as stipulated in drawing and operation with good smooth.

Model and Meaning

Highway guard rail roll forming machine

YX85-310/506

Guard rail is steel material. It is a continuous structure in which corrugated steel guardrails are spliced to each other and supported by the main column. The effect of the vehicle on absorbing energy during its collision is not easy to be destroyed, and it can also protect the vehicle and the passengers.

The forming of the highway guardrail increases the appearance and increases the strength of the slab. Both are available. The automatic production line is extruded, the surface is clean and undamaged, and the corrosion resistance is extremely strong. The surface treatment is mature; anti-corrosion, anti-aging and anti-corrosion The characteristics of drying, high and low temperature, the service life in outdoor environment can reach 10-25 years; The product structure is concise, beautiful and practical, easy to transport, install, good anti-theft performance, limited by actual terrain, for mountain, slope, multi-bend The zone has strong adaptability and moderate cost, which is suitable for large-scale adoption.

Guard rail roll forming machine is most flexible and durable for making highway barriers.

Technical Parameters

Guardrail roll forming machine Parameter

| Usage | Highway Guardrail Production |

| Steel Material | Cold-rolled strip steel, Galvanized sheet |

| Material Thickness | 3.0-4.5mm |

| Yield Strength | Q250-300MPa |

| Forming Product width | 310/506mm |

| Forming Speed | 8-12m/min |

| Forming Mail Power (KW) | 18.5KW*2PCS |

| Hydraulic Power (KW) | 30KW |

| Voltage | Customizable |

Double wave corrugated guardrail, length 4320mm, plate width 310mm, wave depth 85mm, plate thickness 3mm/4mm.

Three-wave corrugated guardrail, length 4320mm, board width 506mm, wave depth 85mm, board thickness 4mm.

Special design guard rail customized is available.

NAVIGATION

Tel: +86 755 2824 6186

Mob: +86 188 1435 5377

Fax: +86 755 2883 9980

E-mail: sales@superdamachine.com

Skype: live:demiwu2014

WhatsApp: +86 188 1435 5377